| Target weight | Actual weight | ||

| Hull wood | 775g |

N/A |

|

| Fibreglass | 603g |

1580g |

|

| Resin | 500g |

||

| Rudders | 365g |

||

| Rudder housing | 545g |

||

| Total | 2788g |

||

Hull 4

12th August update.

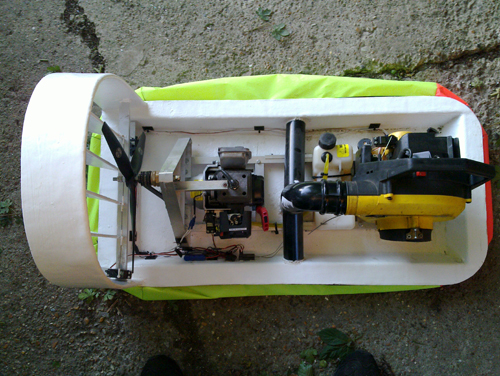

The final craft....

Above you can see the red pull start handle for the thrust engine and the air intake on the leafblower, with the improved impeller.

Above you can see the two fillers for the fuel tanks, and the inverted exhaust on the thrust engine, so that the gasses go backwards away from the lift engine air intake.

Above you can see what all the competitors will see.... Me heading off into the distance.......

Fitted safety cages to thrust and lift fans, but its ruined the look of the beast.

Now we're finally ready. Just mix up some super-unleaded with the 2-stroke oil on Saturday morning.

8th August update.

Going for a trial run with the war badger.

Shifted the weight balance forward one notch and fitted the 14" prop

Result ! it only works!

We're back in the hunt, the only issue left to resolve is the skirt gets dragged under and damaged when we hit debris so I need to add some protective inserts.

27th July update

I decided that the impeller was too coarse and was costing me lift, so I got an impeller from a Stihl BG85 and fitted that in its place.

23rd July update

Here's hull 4 ready to go, just some minor modifications to do.

Here (below) is the view most other teams will see the most

New impeller ordered to improve the efficiency of the blower.

Adjustable chassis mounts to allow weight distribution to be optimised

Simple air tube design this time.....

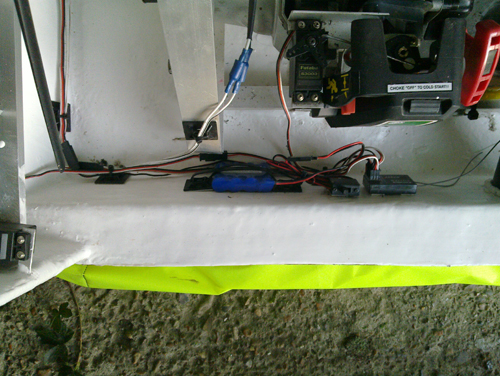

Radio gear installed

20th June update

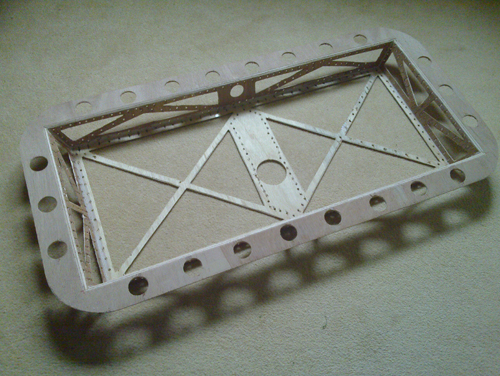

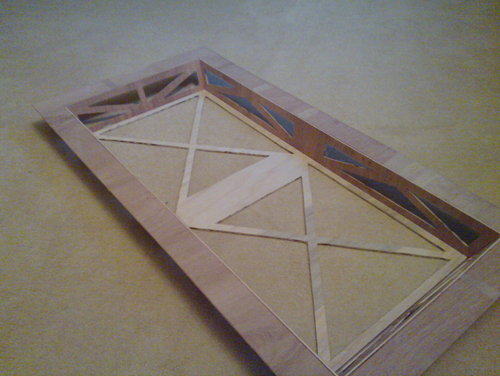

Rear hoop contains the cross beams for the rudders.

This will be fibreflassed to the hull

13th June update

Hull 4a now trimmed and marked for front end shaping.

The fine finish fibreglass on the top and sides will mask the fibres that can still be seen on the base. Once the topcoat has been applied it should allow a high gloss unblemished finish. (this is the key reason for Hull 4a)

Steering structure now in design stage being optimised for the fibreglass construction needs.

12 June update

Decided that the fibreglass process I'd started was flawed, so started again. Not really hull 5 cos I'd only glued a few bits together.

Here's Hull 4a completed and still in its mold waiting to cure.

Hull 4a in its mold just completed, you may spot hull 4, hull3 and hull 2 in the background, and the very first test bed with the blue bag skirt....

10th June update

On inspection of the hull I have decided to restart Hull 4. I was not going to get the finish I was looking for as I had already completed a critical section of the construction.

Hull 4a will be formed in a mold using just fibreglass. This should allow the high quality finish I'm looking for.

6th June update

Ran out of resin, so while waiting for more I've progressed the rest of the hull. Due to the light weight hull I needed to make the other bits stand alone, so I've got the engines on one structure.

It needs a new air tube too

It'll look something like this.....

4th June update

First layer of fibreglass laid in. Due to the lack of support the edges have been done first then the centre sections will be worked in once the first section has cured.

2nd June update

Took more material away, now wood section down to 480g

Laid out inner layer of fibreglass weighing 188g so could be as low as 855g plus resin.....

1st June update

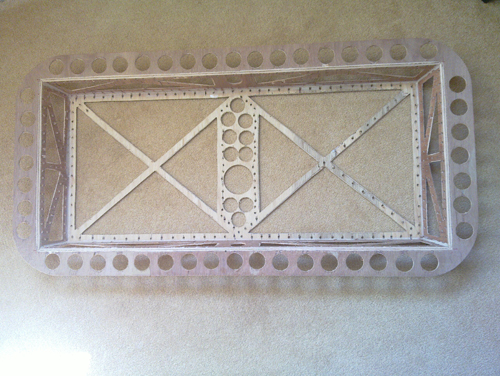

Drilled the 70mm air pipe and 35mm cross pipe openings. Then lightened the topdeck with 22 additional 35mm holes.

Now need to decide if should risk weakening the top deck further by drilling an additionl twenty six 35mm holes in between each of the current ones. That may get it under 500g

31st May update

All edges of the wood rounded and smoothed and then drilled for lightening.

Now only 623g with corners to be cut off yet.....

30th May update

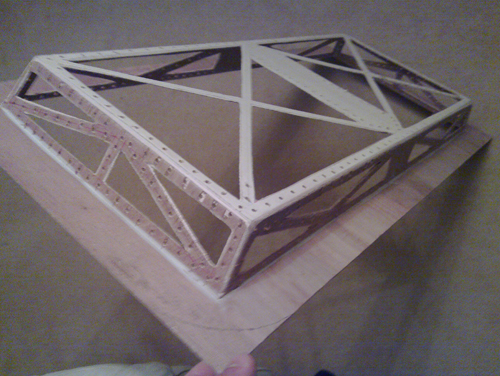

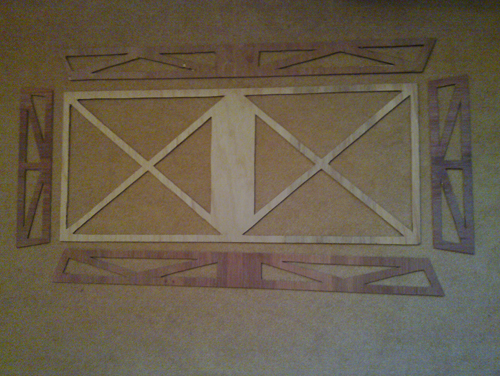

Gone for the general Hull 2 design of the V hull. But, lightweight.

Decided to go for a composite wood / fibreglass hull. The wood will form a skeleton for the fibreglass.

The key focus this time is weight, I know the bits all work when they're bolted together, just need to make it as light as possible.

3.6mm ply hull cut out, then sections removed to reduce weight

Lightweight sections glued together

Standard 70mm deep hull

Remarkably flex free

Next task, smooth and reduce weight more, with loads of holes drilled every where. This serves two purposes, reduces weight more and allows the resin to key to the skeleton.