Team PAYNTRIX 2010 Hovercraft Challenge entry

Welcome to my hovercraft design studio

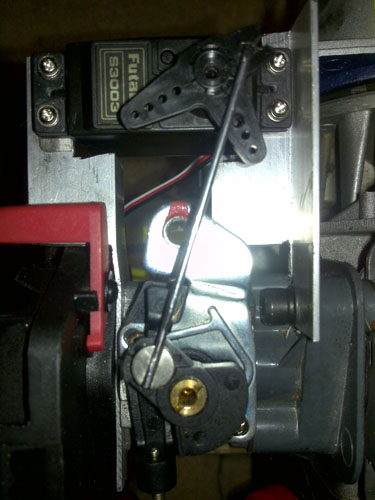

The initial servo attachment struggled with the forces and kept humming. So I thought I'd try and reduce the return spring pressure.

Throtle link bar drops into the slot on the silver bolt

The return spring is between the carb top plate and the throtle slider. The spring is like a clock spring and is hooked into position on the under side of the carb plate. I cut a new slot in the plate but then it was too weak, so another alternative is needed.

Reversing the action of the servo improved the forces and it seemed to work OK.

I fabricated a couple of brackets that mount to the carb and it works a treat.

And looks pretty tidy too.

Just waiting on the drive shaft now and thrust is done.

After the disaster of engine 1, I hope engine 2 will last longer.

At first the nose piece, housing the clutch, looked to be a disadvantage, but it has turned out to be good as it allows clean air to the prop.

Simple Pull start to get the thrust engine running

Mounts cut to shape to match the mounting points on the engine casing

Then glued together. There will be an angle bracket on the front and rear faces, so the glue won't be doing much but add some stiffness.

Servo attachment to the throttle is the next task, but initial trial has identified the return spring a bit too strong.

Adjustments in progress.

Initial install has identified as expected that the air tube that earnt the craft the name Titanic limits the space envelope for the prop.

A couple of 45 degree elbows will cure this and additionally improve the weight balance which hadn't considered 684grams of rudder assembly.

Thrust is coming from a 33cc strimmer engine and a 14" pusher prop.

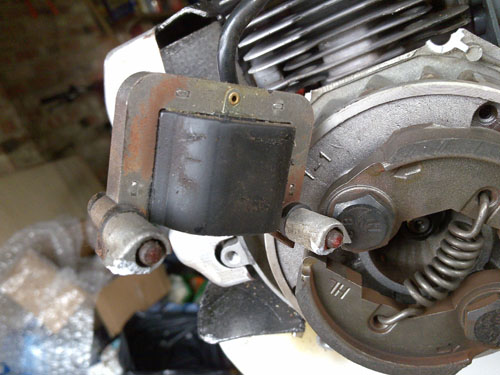

There was a minor hitch with the thrust engine though...

I took the clutch housing off to get a transfer shaft made and then thought I'd fire the engine up to see how it sounded.

Unfortunately I didn't consider the clutch plates would move out as I revved it up.

So when they did the coil assembly was there to take the impact.

Result.

Smashed coil pack and clutch plate

Fractured engine mount

Super extended clutch spring

Engine 2 now on order.....